Vacumetros are essential tools in various industries, providing accurate measurements of vacuum levels to ensure optimal performance and safety. In this guide, we’ll explore the intricacies of vacumetros, their applications, working principles, types, benefits, selection criteria, and maintenance tips.

Introduction to Vacumetros

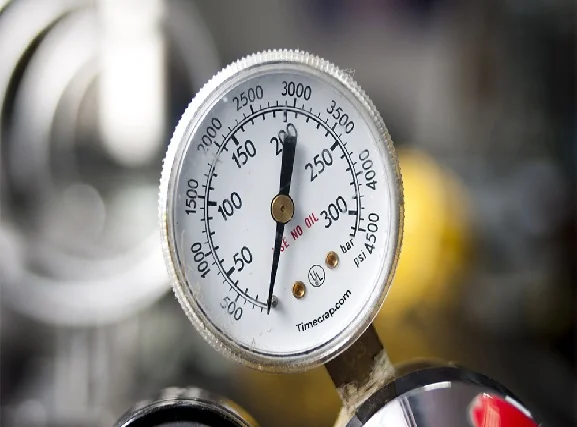

Vacumetros, also known as vacuum gauges, are devices used to measure the pressure in a vacuum. They play a crucial role in industries such as manufacturing, automotive, aerospace, and scientific research. By providing precise vacuum readings, vacumetros help maintain quality standards and ensure efficient processes.

What are Vacumetros Used For?

Vacumetros are employed in a wide range of applications, including:

- Vacuum systems monitoring

- Leak detection

- Vacuum chamber testing

- Process control in manufacturing

- Environmental monitoring

Understanding How Vacumetros Work

Basic Principle

Vacumetros operate based on the principle of measuring the pressure difference between the vacuum and the surrounding atmosphere. They typically consist of a sensor or gauge connected to the vacuum system, which detects the pressure exerted by the absence of air molecules.

Components of a Vacumetro

Key components of a vacumetro include:

- Pressure sensor

- Display unit

- Calibration controls (in some models)

- Connecting ports

Types of Vacumetros

Mechanical Vacumetros

Mechanical vacumetros utilize physical mechanisms such as bourdon tubes or diaphragms to measure vacuum levels. They are reliable and cost-effective but may have limited accuracy compared to digital counterparts.

Digital Vacumetros

Digital vacumetros use electronic sensors and display units to provide precise vacuum readings. They offer enhanced accuracy, customizable features, and compatibility with digital systems for data logging and analysis.

Benefits of Using Vacumetros

- Accurate vacuum measurement

- Early detection of leaks or system malfunctions

- Improved process control and product quality

- Enhanced safety in vacuum operations

How to Choose the Right Vacumetro

When selecting a vacumetro, consider factors such as:

- Required vacuum range

- Accuracy and precision

- Compatibility with existing equipment

- Portability and durability

- Budget constraints

Tips for Using Vacumetros Effectively

- Follow manufacturer’s instructions for installation and calibration.

- Regularly calibrate the vacumetro to maintain accuracy.

- Use appropriate accessories and fittings for secure connections.

- Keep the sensor clean and free from debris for accurate readings.

Common Mistakes to Avoid When Using Vacumetros

- Neglecting regular calibration and maintenance.

- Overlooking compatibility issues with vacuum systems.

- Ignoring warning signs of potential leaks or system failures.

- Using vacumetros beyond their specified range or operating conditions.

Maintenance and Care of Vacumetros

To prolong the lifespan and ensure optimal performance of vacumetros, follow these maintenance tips:

- Clean the sensor and display unit regularly.

- Store the vacumetro in a dry and dust-free environment.

- Replace worn-out components or damaged parts promptly.

- Schedule periodic calibration and testing by certified technicians.

Industry Applications of Vacumetros

Vacumetros find extensive use in various industries, including:

- Semiconductor manufacturing

- Pharmaceuticals

- Food packaging

- HVAC systems

- Automotive diagnostics

Future Trends in Vacumetro Technology

Advancements in vacumetro technology are expected to focus on:

- Miniaturization for portable applications

- Integration with IoT for remote monitoring

- Enhanced sensitivity and accuracy

- Automation of calibration and maintenance processes

Conclusion

Vacumetros are indispensable tools for measuring vacuum levels in diverse industrial settings. By understanding their working principles, types, benefits, and maintenance requirements, users can optimize processes, improve product quality, and ensure safety. As technology continues to evolve, vacumetros will remain essential for efficient vacuum system management and quality control.

For Get More Information

- Exploring Global Seas on Your Plate: The Culinary Symphony of Saltwater Coastal Grill

- Unveiling the Intriguing Story of Bruce Wilpon Wife: A Tale of Love and Legacy

- Matt Rife Net Worth

- Unraveling the Storyof Tobyn Jacobs Parents : A Comprehensive Guide

- Drink Champs: Happy Hour Episode 4 – Unveiling the Cheers and Conversations