In today’s rapidly evolving technological landscape, the journey from a simple idea to a fully functional electronic device is both intricate and fascinating. This process, often referred to as electronic design and manufacturing (EDM), involves multiple stages, each requiring precision, creativity, and technical expertise.

Let’s delve into the steps that transform innovative concepts into tangible electronic products.

Research and Feasibility Study

The first step is looking into the idea to see if it can work. This part is called the research and feasibility study. Think of it like seeing if you can build your dream toy with the pieces you have. People who are good at making electronic things, called electronic design services, help with this.

They check to see if your idea can turn into something real, how much it might cost, and what stuff they need to make it. This is important because it helps to know if the idea is good to go before spending more time and money on it.

Design and Development

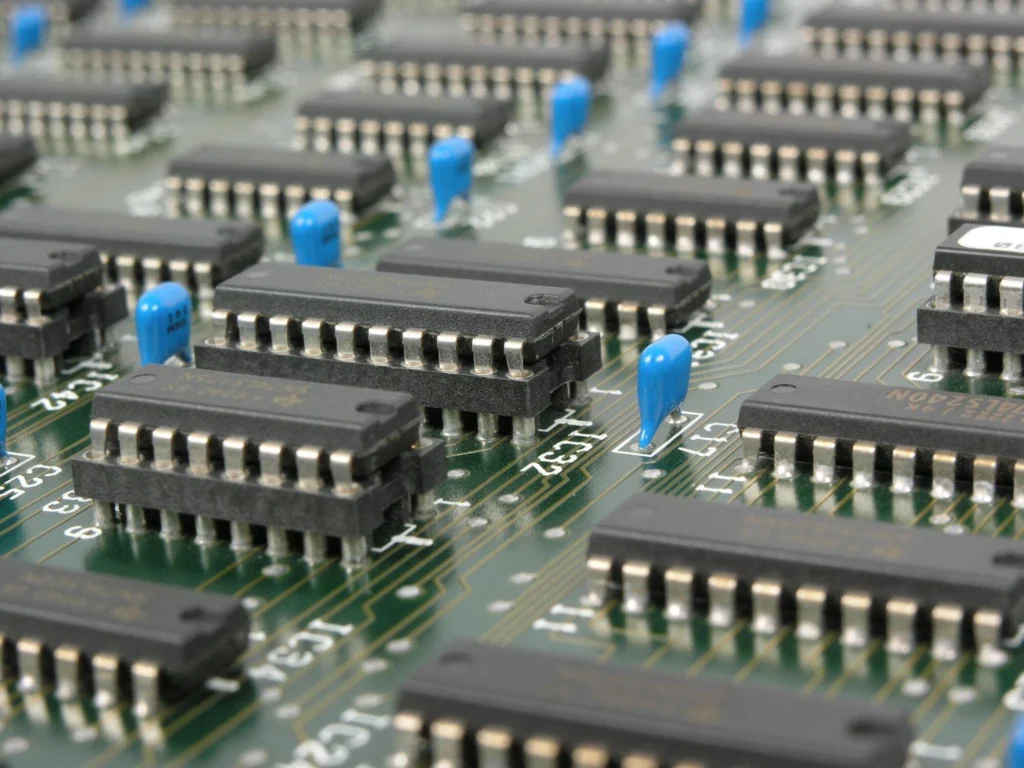

After lots of thinking and studying, it’s time to make things! Here, big ideas start to look real. People draw pictures of what they want to make. They pick special parts that will help their idea work. Sometimes they use computers to help see how it will look and work.

This part is like using building blocks but for new gadgets. They try again and again to make it just right. They also make a fun interactive product demo. This means you can play with it to see how it works before it’s made. It’s like a test to make sure everyone will like it.

Prototyping

Next comes making a mini version of the idea, which is called a prototype. Think of it like making a small sample or a rough copy to see if the idea can work as a gadget. This step is very important because it helps to find problems and fix them without spending a lot of money.

People use different tools and pieces, including something called electronic power design, to make the prototype. Electronic power design is about making sure the gadget can get and use power the right way so it can do its job. Making a prototype is like practice before making the real thing, to check everything is okay.

Testing and Validation

After making the prototype, it’s time to test. This means checking to see if the gadget works the way we want. Testing is like trying out a new toy to find out if it’s fun or if something is wrong. People use it a lot and in different ways to make sure it’s safe and does its job right.

If they find problems, they go back and fix them. This step is like making sure that your toy won’t break the first time you play with it. Testing makes sure everything is good and ready for the next step.

Learn All About Electronic Design and Manufacturing

In the end, making electronic design and manufacturing is super cool but also hard. You have to think, draw, build a tiny version, and check it a lot to make sure it’s awesome. People who make gadgets follow these steps to turn brainy ideas into real things you can play with or use.

It’s all about dreaming it, making it, and fixing it until it’s just right. And that, friends, is how we get all the cool tech toys and tools we use every day.

Did you find this article helpful? Check out the rest of our blog.